I’ve had a few more gos at making smoke and, well, there’s still work to be done.

2nd Attempt

There were two main issues with the first attempt. The smoke was intermittent, and I needed to manually shake the ramp. In the second attempt I tried to take care of both problems with one stroke. I mounted a fan to the underside of the ramp. This would induce air circulation, and the spinning would vibrate the ramp. I settled on the fan out of a a hair-drier. The idea was appealing for several reasons:

- An old hair drier is $3 at the thrift store.

- A hair drier uses 120V AC. I wouldn’t need a separate source to power it

- It’s a fan.

So I got the fan out and mounted it to the ramp. It turns out that this idea wasn’t all that good.

- Mounting the fan in the middle of the ramp like that did little to improve circulation.

- The fan didn’t vibrate all that much

- It turns out the motor was actually DC. They use the heater coil as a resistor to get the voltage they need, then rectify it with a diode. It’s a brilliant, low cost solution for them. It was a pain in the butt for me.

- The fan was LOUD. You know, like a hair drier.

So other than learning how a hair drier is wiried, attempt 2 was pretty much a bust. I got the same smoke performance from a louder unit that needed a 12V power supply.

3rd Attempt

The fan didn’t really do much in the second attempt. It didn’t vibrate, and didn’t improve airflow. In the 3rd attempt I tried to fix both problems.

To increase the fan’s vibration, I decided to give it a little off-center weight. Inserting a screw into one of the blades shifted the center of gravity, and made it vibrate like a champ. This didn’t do anything to help the noise / circulation issues though. I try to be nice to my neighbors whenever I can, and 4-5 hours of vibrating hair drier noise just isn’t nice.

So I shifted gears. Instead of a constantly vibrating fan with on-off heat, I decided on an intermittent vibrating fan with more consistent heat. Since the initial smoke issues were caused by the On-Off heat control, maybe a more constant heat would lead to constant airflow / smoke. The Fan was relegated to vibration duty, turning on periodically to help the wood settle.

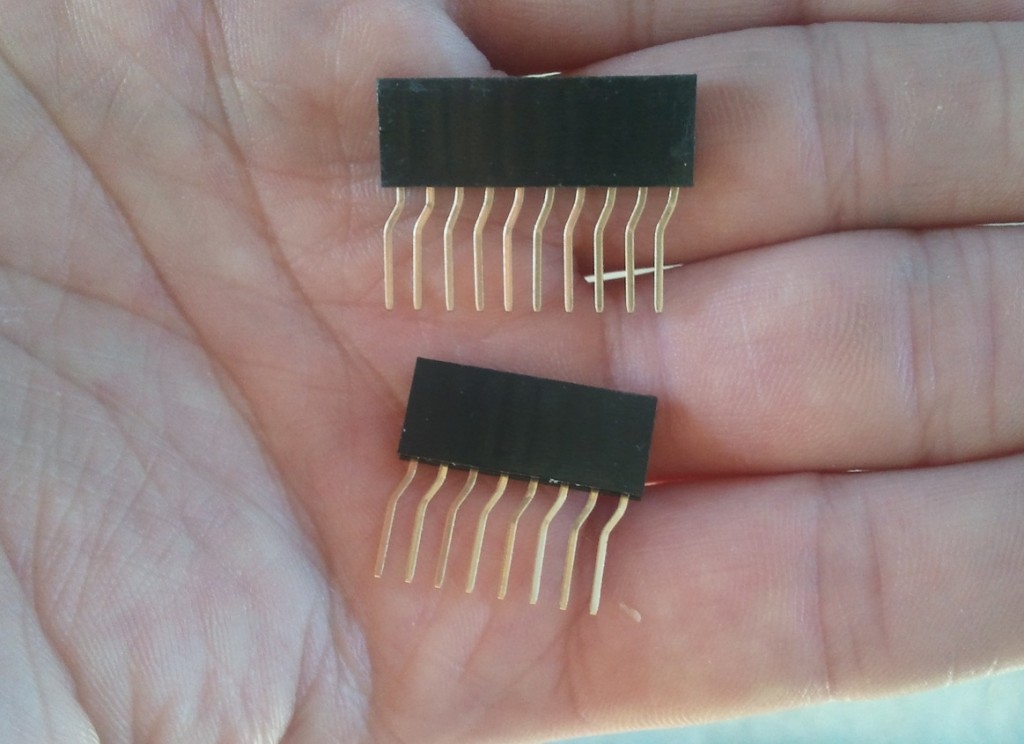

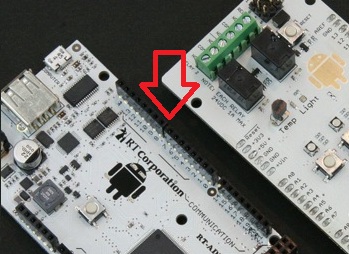

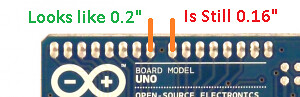

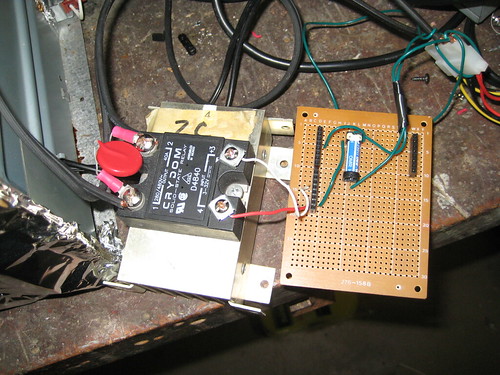

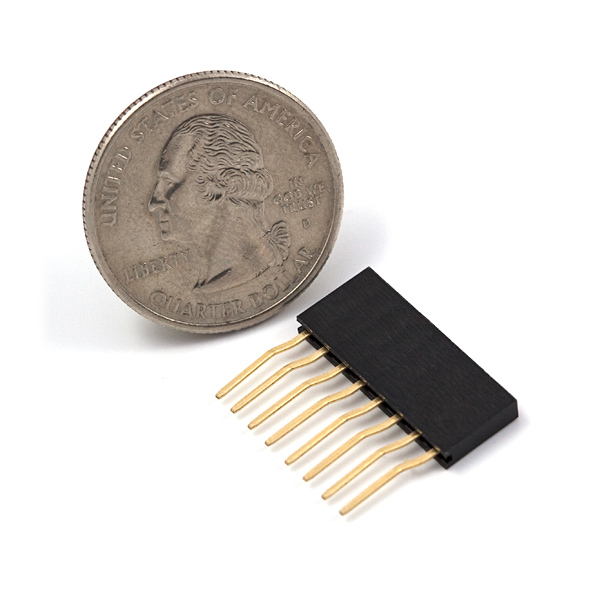

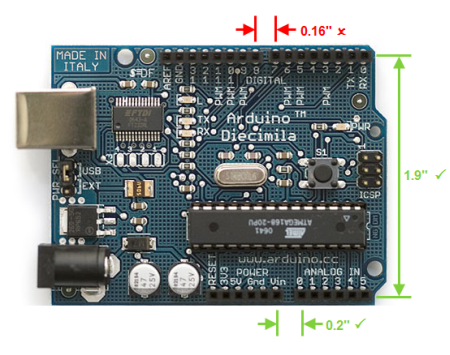

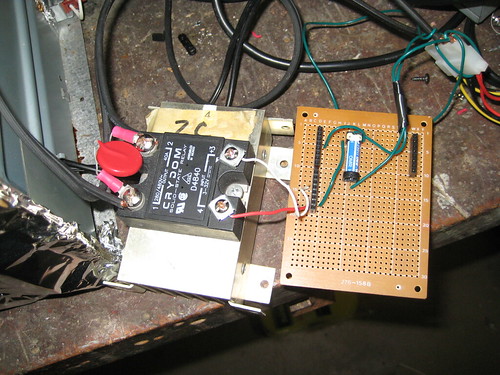

I built an arduino sheild (yes I used an offset header) to:

- Send a 25% output to an SSR controlling the heaters.Â

- Vibrate the fan for 5sec every 10 min (more than enough to help the wood settle)

Great plan right? I got everything set up, saw the smoke start, and walked away for 30 min. Anyone know what happened next? Anyone? Yes. You in the back. The heaters added more and more heat to the chamber? More than the air could remove, even though the airflow was increasing with temperature? You’re right! I had suspected that this might happen, just not so quickly.Â

…I came back to a fire. It was contained within the box, and the box was alone on an a stone patio. There wasn’t any danger, but the fan was cooked. damn. Here’s some carnage photos where you can see the vibration screw:

So What Now?

I was hoping to be able to macgyver my way through this thing using aluminum foil and tape. I’m going to have to up my game a bit. In future attempts I’m going to start from overkill and work my way down, rather than the bottom up method I’ve been using.  So that means:

- Really sealing the chamber.

- Using an external fan

- Using dampers to control airflow in and out.

- Mounting the vibration mechanism OUTSIDE the fire box so it doesn’t get smoke/fire damage

- More precise temperature control. That’s right. PID control. I said overkill. I meant it.